Study on metallurgical properties of semi-solid metal aluminium alloy 5083 welding by gas metal arc welding

Keywords:

Gas metal arc welding, semi-solid state aluminium alloy 5083, lap jointAbstract

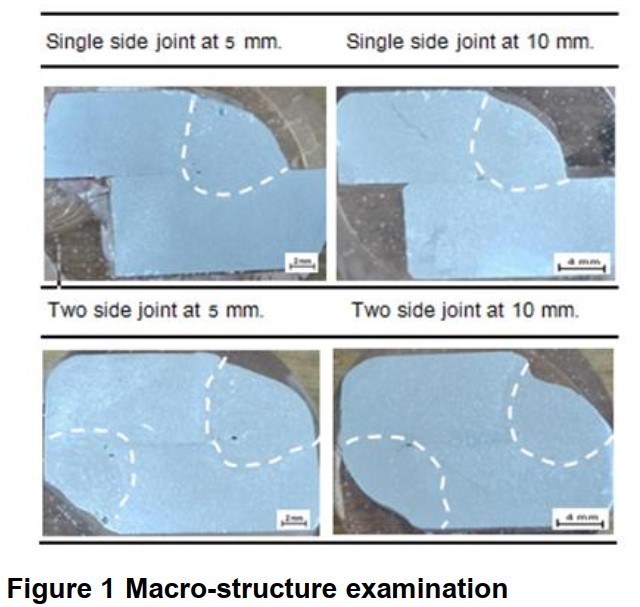

The study was aimed to investigate the metallurgical properties of semi-solid metal aluminium alloy 5083 welding using gas metal arc welding, with the variation of 5, 10 mm, and one-sided lap joint. The weld is characterized by a complete melting, and macro structure had no twist and cracks caused by the residual stresses in the weld. The small amounts of porosity were observed throughout the weld area. From the twoway lap joint at 10 mm, the penetration depth is better, and the porosity is less than the 5 mm lap joint. The microstructure of the base metal is composed of spheroidal grain structure (α), mixed with eutectic phase (Mg + Si). The pore size is 5 to 20 microns. It has a uniform distribution of Mg2Al3, which is smaller than the structure of the heat affected area. From the inspection does not show the crease of the weld. It showed that 5083 semi-solid aluminum alloys can lap joint with the gas metal arc welding

References

2. Karadeniz E, Ozsarac U, Yildiz C. The Effect of process parameters on penetration in gas metal arc welding processes. Mater Des. 2007;28:649-56.

3. Shah LH, Mohamad UK, Yaakob KI, Razali AR, Ishak M. Lap joint dissimilar welding of aluminium AA6061 and galvanized iron using TIG Welding. J Mech Eng Sci (JMES). 2016;10(1):1817-26.

4. Praveen P, Yarlagadda PDKV. Meeting challenges in welding of aluminium alloys through pulse gas metal arc welding. J Mater Proc Technol. 2005;164-165:1106-12.

5. Lu SL, Wu SS, Zhu ZM, An P, Mao YW. Effect of semi-solid processing on microstructure and mechanical properties of 5052 aluminum alloy. Trans Nonferrous Met Soc China. 2010;20:S758-S62.

6. Liu Y, Wang W, Xie J, Sun Shougung, Wang L, Qian Y, et al. Microstructure and mechanical properties of aluminum 5083 weldments by gas tungsten arc and gas metal arc welding. Mater Sci Eng. 2012:549:7–13.

7. Cueca F, Solano E, Patarroyno A, Morales A, Rojas F, Munoz R. Study of the weld ability of aluminum alloy 5083 H116 with pulsed arc GMAW (GMAW-P). Ship Sci Technol. 2012;6(11):43-56.

8. Arun Narayanan., et al. Influence of gas tungsten arc welding parameters in aluminium 5083 alloy. International Journal of Engineering Science and Innovative Technology. 2013; Vol.2, Issue 5

9. Haken M, Lebaili S, Miround J, Toukail S. Welding and characterization of 5083 aluminum alloy. Metal. 2012;5:23-25.

Downloads

Published

How to Cite

Issue

Section

License

ผู้นิพนธ์ต้องรับผิดชอบข้อความในบทนิพนธ์ของตน มหาวิทยาลัยพะเยาไม่จำเป็นต้องเห็นด้วยกับบทความที่ตีพิมพ์เสมอไป ผู้สนใจสามารถคัดลอก และนำไปใช้ได้ แต่จะต้องขออนุมัติเจ้าของ และได้รับการอนุมัติเป็นลายลักษณ์อักษรก่อน พร้อมกับมีการอ้างอิงและกล่าวคำขอบคุณให้ถูกต้องด้วย

The authors are themselves responsible for their contents. Signed articles may not always reflect the opinion of University of Phayao. The articles can be reproduced and reprinted, provided that permission is given by the authors and acknowledgement must be given.