The optimum conditions of process of quick-cooking brown rice using response Surface methodology

Keywords:

Quick cooking brown rice, Instant productsAbstract

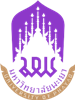

This research aimed to study the effect of moisture content, pressure and drying temperature on texture properties of quick cooking brown rice of 2 varieties: Red Hom Mali Brown and Rice Hom Mali Brown Rice using response surface methodology (RSM) and experimental design is Central Composite Design (CCD). Hardness and chewiness were used as responses because of high R2 and there is rice cooked from a microwave cooker as a reference value. The optimum conditions were overloid area of responses that have hardness and chewiness similar cooked rice. The observed value from 3 conditions and predicted values were not different at 95% level confidence. The Verification from optimum process, response value for quick cooking brown rice process with suitable condition as follows: Red Hom Mali Brown Rice was using production conditions at Initial humidity 55%, pressure 10 lb / in2, and drying temperature 160°C. Hom Mali Brown Rice Brown using production conditions at Initial humidity 70%, pressure 5 lb / in2 and drying temperature 200°C. The best conditions and predicted values were not different at 95% level confidence. Hardness and chewiness of rice were decreased, when increase moisture content and pressure. While higher drying temperature cause increasing in hardness and chewiness. Quick cooking rice was lower density than raw rice because expanded and porosity in kernels.

References

Ahromrit A, Ledward D.A. and Niranjan K. High pressure induce water uptake characteristics of Thai glutinous rice. J. Food Eng. 2006;72: 225-233.

Baz A.A., Hsu J.Y. and Scoville E. Preparation of quick cooking rice. U.S. Patent 1992;5, 089, 281.

Elbert G, Tolaba M. P and Suarez C. Effect of drying conditions on head rice yield and browning index of parboiled rice. J. Food Eng. 2001; 47(1): 37-41.

Leelayuthsoontorn P and Thipayarat A. Textural and morphological changes of Jasmine rice under various elevated cooking conditions. Food Chem. 2006; 96(3): 606–613.

Park J K, Kim S S and Kim K O. Effect of milling ratio on sensory properties of cooked rice and on physicochemical properties of milled and cooked rice. Cereal Chem. 2001;78: 151-156.

Prakash M, Ravi R,. Sathish H.S, Shyamala J.C, Shwetha M.A. and Rangarao G.C.P. Sensory and instrumental texture measurement of thermally processed rice. J. Sensory stud. 2005; 20 (3): 410-420.

Ramesh M.N. and Rao P.N.S. Drying studies of cooked rice in a vibro fluidised bed drier. J. Food Eng. 1996; 27: 389-396

Smith D.A., Rao J.A.,Liuzzo and Champagne E. Chemical treatment and process modification for producing improve quick cooking rice. J. Food sci. 2002; 50: 926-931.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Naresuan Phayao Journal

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

ผู้นิพนธ์ต้องรับผิดชอบข้อความในบทนิพนธ์ของตน มหาวิทยาลัยพะเยาไม่จำเป็นต้องเห็นด้วยกับบทความที่ตีพิมพ์เสมอไป ผู้สนใจสามารถคัดลอก และนำไปใช้ได้ แต่จะต้องขออนุมัติเจ้าของ และได้รับการอนุมัติเป็นลายลักษณ์อักษรก่อน พร้อมกับมีการอ้างอิงและกล่าวคำขอบคุณให้ถูกต้องด้วย

The authors are themselves responsible for their contents. Signed articles may not always reflect the opinion of University of Phayao. The articles can be reproduced and reprinted, provided that permission is given by the authors and acknowledgement must be given.