Development of a low-calories dried gummy jelly product from Krueo Ma Noy leaves (Cissampelos pareira L.)

Main Article Content

Abstract

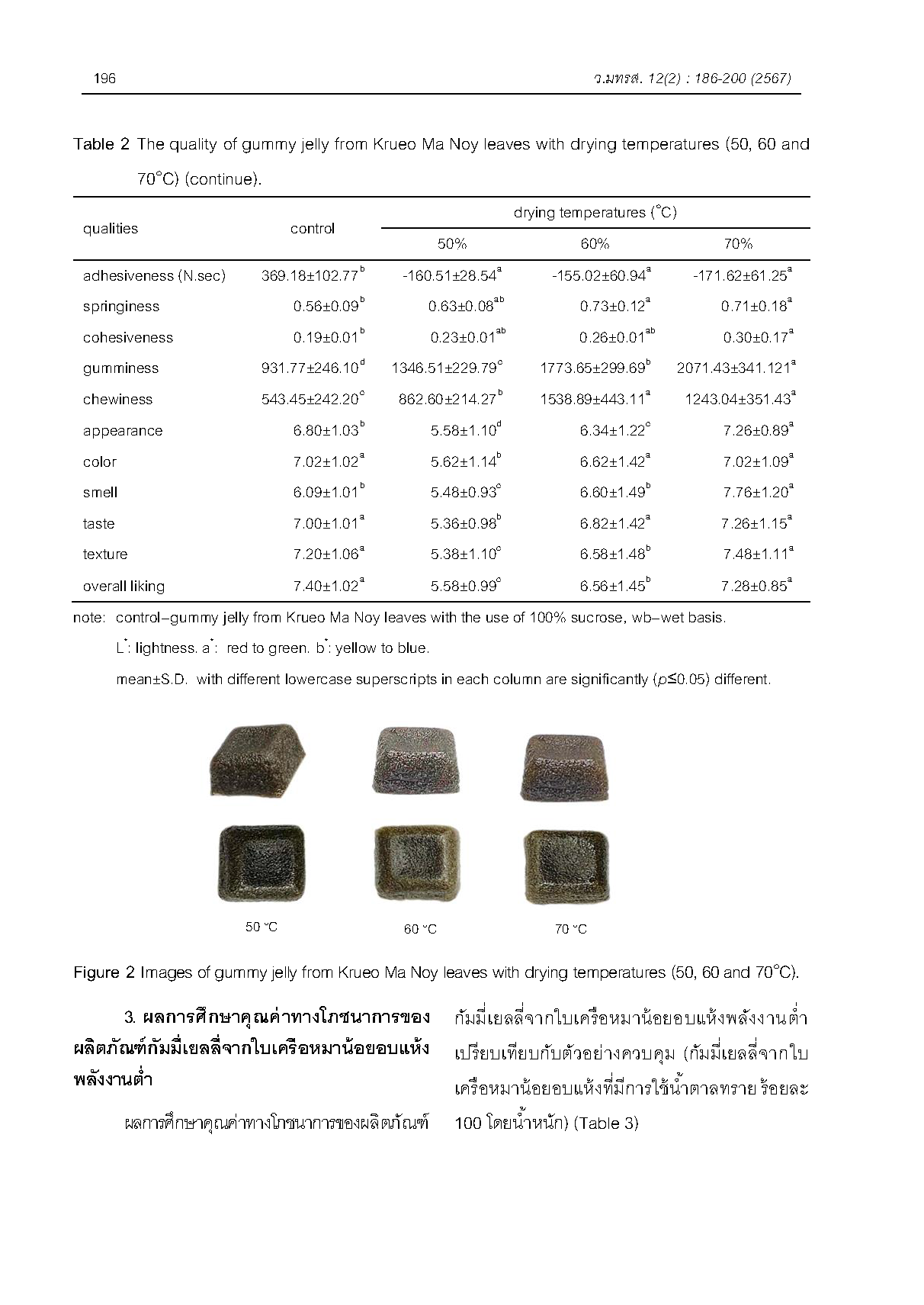

The objective of this research was to study the effects of reducing sucrose content 25, 50 and 75% by weight in low energy gummy jelly from Krueo Ma Noy Leaves (Cissampelos pareira L.) compared to the control sample (100% sucrose). It was found that the reduction in sucrose content led to increase moisture content and an upward trend in lightness (L*) and yellow color (b*) values. The red color value decreased to negative (-a*), resulting in a deep green product with translucency. The texture quality showed that gummy jelly with reduced sucrose content exhibited no significant difference in texture properties compared to the control. Sensory evaluation using a 9-point hedonic scale showed that gummy jelly with 50% sucrose had similar liking scores to the control, ranging from 6.46 to 6.93, making it a suitable formulation. The study of drying temperatures revealed that higher drying temperatures resulted in reduced moisture content and water activity, meeting the criteria for general consumption of gummy jelly products. Higher drying temperatures led to a decrease in L*, while hardness, springiness, cohesiveness, gumminess, and chewiness increased. Regarding sensory evaluation, gummy jelly dried at 70๐C received higher liking scores for appearance, texture, and overall preference compared to 60๐C and 50๐C, with scores ranging from 7.26 to 7.48, indicating moderate to high acceptance of the product. Nutritional values of the product revealed protein, fat, carbohydrate, and crude fiber contents of 0.72, 0.02, 95.30 and 2.98 g/ 100 g, respectively. The product had reduced fat and carbohydrates, resulting in a decrease in total energy to 384.26 kcal. Furthermore, the product contained higher levels of crude fiber and β-carotene than the control. Therefore, this product meets consumers’ energy restriction needs well.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Published manuscript are the rights of their original owners and RMUTSB Academic Journal. The manuscript content belongs to the authors' idea, it is not the opinion of the journal's committee and not the responsibility of Rajamangala University of Technology Suvarnabhumi

References

Absolute report. (2022). Jellies and gummies market worth USD 2588 million by 2022-2028. Retrieved 11 July 2022, from https://www.globenewswire.com/en/news-release/2022/07/11/2477192/0/en/Jellies-and-Gummies-Market-Worth-USD-2588-million-by-2022-2028-Opportunities-Challenges-Drivers-Trends-Key-Players-Regional-Analysis.html

AOAC. (2019). Offical methode of analysis of AOAC (International 17th Ed.). Gaithersburg, MD, USA: Association of Analytical Communicaties.

Delgado, P., & Bañón, S. (2015). Determining the minimum drying time of gummy confections based on their mechanical properties. Journal of Food, 13(3), 329-335.

Evageliou, V., Mazioti, M., Mandala, I., & Komaitis, M. (2010). Compression of gellan gels. Part II: effect of sugars. Food Hydrocolloids, 24(4), 392-397.

Ergun, R., Lietha, R., & Hartel, R. W. (2010). Moisture and shelf life in sugar confections. Critical Reviews in Food Science and Nutrition, 50(2), 162-192.

Hiran-akkharawong, I., & Panyathitipong, W. (2015). Utilization of fresh coconut syrup in crispy jelly product. RMUTSB Academic Journal, 3(2), 109-119. (in Thai)

Kanpairo, K., & Srisuk, S. (2016). Production and Utilization of Etlingera elatior (Jack) R.M. Smith for nutraceutical food product (research report). Yala: Yala Rajabhat University. (in Thai)

Keawsa-ard, S., Chuanphongpanich, S., & Daducale, A. (2020). Development of gummy jelly from Mesua ferrea Linn. flower extract. Thai science and technology journal, 28(12), 2185-2200. (in Thai)

Lindley. (2002). Influence of gelatin and isomaltose on gummy jelly. International Food Research Journal, 25(2), 776-783.

Meilgaard, M., Civille, G. V., & Carr, B. T. (1999). Sensory evaluation techniques (3rd Ed.). Boca Raton, FL, USA: CRC Press.

Nadian, M. H., Rafiee, S., Aghbashlo, M., Hosseinpour, S., & Mohtasebi, S. S. (2015). Continuous real-time monitoring and neural network modeling of apple slices color changes during hot air drying. Food and Bioproducts Processing, 94, 263-274.

Pakkaew, Y. (2016). Ma-noi natural pectin-benefit from local herb. Food Journal, 46(1), 15-20. (in Thai)

Palachum, W., Klangbud, W. K., & Chisti, Y. (2023). Novel nutritionally-enriched gummy jelly infused with nipa palm vinegar powder and nipa palm syrup as functional food ingredients. Heliyon, 9(11), e21873.

Periche, A., Heredia, A., Escriche, I., Andrés, A., & Castelló, M. L. (2014). Optical, mechanical and sensory properties of based-isomaltulose gummy confections. Food Bioscience, 7, 37-44.

Promsakha Na Sakon Nakhon, P., Jangchud, A., & Jangchud, K. (2011). Process development for pectin production from Krueo Ma Noy leaves (Cissampelos pareira L.). In Proceedings of 49th Kasetsart University Annual Conference: Agro-Industry (Ed.), Proceedings of 49th Kasetsart University Annual Conference (pp. 499-507). Bangkok (Thailand): The Thailand Research Fund. (in Thai)

Puttame, K., Sawasdikarn, J., & Chitphutthanakul, S. (2014). Development of gummy jelly of Nham Dang fruit product (research report). Chanthaburi: Rambhai Barni Rajabhat University. (in Thai)

Rittilert, P., & Warin, K. (2020). Karanda (Carissa carandas L.) gummy jelly product. Journal of Science and Technology, 9(2), 342-354. (in Thai)

Rungsardthong, V. (2009). Food processing technology. Bangkok: King Mongkut's University of Technology North Bangkok. (in Thai)

Sangkam, J. (2010). Processing of dried jelly from pennywort juice by heat pump under ultra-violet compared with infrared vacuum drying. (master’s thesis). Chiang Mai University. Chiangmai. (in Thai)

Singthong, J., Cui, S. W., & Goff, H. D. (2004). Stuctural characterization, degree of estertification and some gelling properties of Krueo Ma Noy pectin (Cissampelos pareira) pectin. Cabohydrate Polymers, 58(4), 391-400.

Singthong, J., Ningsanond, S., Cui, S. W., & Goff, H. D. (2005). Extraction and physicochemical characterization of Krueo Ma Noy pectin. Journal of Food Hydrocolloids, 19(1), 793-801.

Suwan, T., Narathapanon, P., Iamsuwan, A., Pongpattanapanich, W., & Kullamethee, P. (2018). Development of Babbler’s Bill leaf carragenan jellies. The Journal of King Mongkut's University of Technology North Bangkok, 28(2), 403-411. (in Thai)

Suankramdee, W., Jirakachaporn, B., & Harnsilawat, T. (2022). Effect of carrageenan and drying time on selected qualities of gummy jelly. In Proceedings of 60th Kasetsart University Annual Conference: Science, Engineering and Architecture, Agro-Industry, Natural Resources and Environment. Proceedings of 60th Kasetsart University Annual Conference (pp. 455-460). Pathum Thani: Prachacheun Research Network. (in Thai)

Teixeira-Lemos, E., Almeida, A. R., Vouga, B., Morais, C., Correia, I., Pereira, P., & Guiné, R. P. F. (2021). Development and characterization of healthy gummy jellies containing natural fruits. Open Agriculture, 6(1), 466-478.

Tau, T., & Gunasekaran, S. (2016). Thermorheological evaluation of gelation of gelatin with sugar substitutes. LWT - Food Science and Technology, 69, 570-578.

The public health ministry. (2000). Notification of the Ministry of Public Health (No. 213) B.E. 2543 (2000). Re: Jam, jelly, and marmalade in sealed containers. Nonthaburi: Ministry of Public Health. (in Thai)

Wiriyacharee, P. (2008). Utilization of cereals and fruits from Royal Project Foundation for improvement of Thai Muesli Bar (research report). Chiangmai: Royal Project Foundation. (in Thai)

Zong, C., Xiao, Y., Shao, T., Chiou, J. A., Wu, A., Huang, Z., Chen, C., Jiang, W., Zhu, J., Dong, Z., Liu, Q., & Li, M. (2023). Alfalfa as a vegetable source of β-carotene: the change mechanism of β-carotene during fermentation. Food Research International, 172, 113104.