Influence of plastically anisotropic on formability in sheet metal using hole expansion test

Main Article Content

Abstract

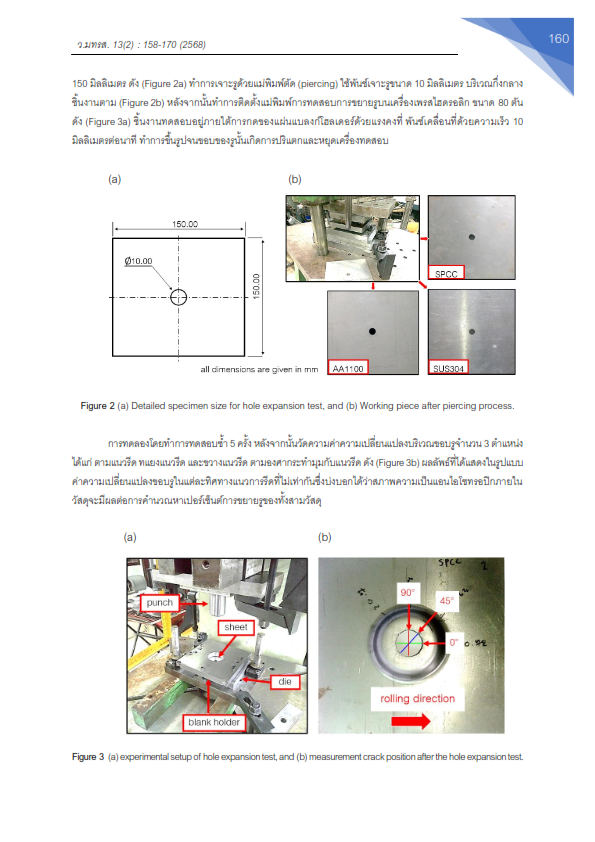

This research aimed to study the effect of anisotropic behavior of materials on the hole expansion ratio (HER) in cold rolled carbon steel sheets, grade SPCC, stainless steel, grade SUS304, and aluminum, grade AA1100 with thickness of 1.20mm. The hole expansion test is considered according to the ISO-16630 standard with both dimension cylindrical flat punch and conical punch at 60 degrees with a 50mm and diameter die of 52.70mm. Square sheets 150×150mm were pierced within 10mm at the center hole. After the test workpiece was formed until it cracked, the changed hole size of the test piece was measured to be the hole expansion ratio obtained from the experiment compared with the hole expansion ratio based on Hill’s 48 anisotropic yield criterion. The major and minor strains in the direction of the test piece were measured as diagonal and transverse rolling along the rolling direction, respectively, in order to determine the anisotropic hole expansion ratio and the anisotropic behavior of the material on the forming limit diagrams. As a result, hole expansion tests were conducted using a flat punch and a conical punch at 60 degrees and coupled anisotropic three-direction (i.e., 0o, 45o and 90o) relative to the rolling direction. The hole expansion ratios of SPCC material were 112.72, 100.56, 115.96, 150.24, 141.16 and 152.92%, respectively. The hole expansion ratios of SUS304 material were 30.04, 44.48, 32.36, 38.76, 51.48 and 39.12%, respectively. The hole expansion ratios of AA1100 material were 15.68, 20.78, 20.22, 20.65, 22.48 and 23.65%, respectively.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Published manuscript are the rights of their original owners and RMUTSB Academic Journal. The manuscript content belongs to the authors' idea, it is not the opinion of the journal's committee and not the responsibility of Rajamangala University of Technology Suvarnabhumi

References

Abedini, A., Narayanan, A., & Butcher, C. (2024). On the flat punch hole expansion test of sheet metals: Mechanics of deformation and evaluation of anisotropic plasticity models. Mechanics of Materials, 191, 104931. https://doi.org/10.1016/j.mechmat.2024.104931

Barlat, F., Brem, J. C., Yoon, J. W., Chung, K., Dick, R. E., Lege, D. J., Pourboghrat, F., Choi, S. H., & Chu, E. (2003). Plane stress yield function for aluminum alloy sheets—part 1: Theory. International Journal of Plasticity, 19(9), 1297-1319. https://doi.org/10.1016/S0749-6419(02)00019-0

Belytschko, T., & Tsay, C. S. (1983). A stabilization procedure for the quadrilateral plate element with one‐point quadrature. International Journal for Numerical Methods in Engineering, 19(3), 405-419. https://doi.org/10.1002/nme.1620190308

Chaimongkon, T., Panich, S., & Uthaisangsuk, V. (2021). Anisotropic fracture forming limit curve and its applications for sheet metal forming with complex strain paths of aluminum sheet. The International Journal of Advanced Manufacturing Technology, 115(11), 3553-3577. https://doi.org/10.1007/s00170-021-07357-z

Chinara, M., Paul, S. K., Chatterjee, S., & Mukherjee, S. (2021). Effect of planar anisotropy on the hole expansion ratio of cold-rolled DP 590 steel. Transactions of the Indian Institute of Metals, 75, 535-543. https://doi.org/10.1007/s12666-021-02444-x

Hill, R. (1948). A theory of the yielding and plastic flow of anisotropic metals. Proceedings of the Royal Society A: Mathematical and Physical Sciences, 193(1033), 281-297. https://doi.org/10.1098/rspa.1948.0045

Kacem, A., Krichen, A., & Manach, P. Y. (2015). Finite element analysis of hole-flanging process with various anisotropy assumptions. The International Journal of Advanced Manufacturing Technology, 80, 11-19. https://doi.org/10.1007/s00170-015-6980-y

Korkolis, Y. P., Brownell, B., Coppieters, S., & Tian, H. (2016). Modeling of hole-expansion of AA6022-T4 aluminum sheets with anisotropic non-quadratic yield functions. Journal of Physics: Conference Series, 734, 032083. https://doi.10.1088/1742-6596/734/3/032083

Kuwabara, T., Hashimoto, K., Iizuka, E., & Yoon, J. W. (2011). Effect of anisotropic yield functions on the accuracy of hole expansion simulations. Journal of Materials Processing Technology, 211(3), 475-481. https://doi.org/10.1016/j.proeng.2014.10.346

Kuwabara, T., Mori, T., Asano, M., Hakoyama, T., & Barlat, F. (2017). Material modeling of 6016-O and 6016-T4 aluminum alloy sheets and application to hole expansion forming simulation. International Journal of Plasticity, 93, 164-186. https://doi.org/10.1016/j.ijplas.2016.10.002

Iizuka, E., Hashimoto, K., & Kuwabara, T. (2014). Effects of anisotropic yield functions on the accuracy of forming simulations of hole expansion. Procedia Engineering, 81, 2433-2438. https://doi.org/10.1016/j.proeng.2014.10.346

Park, H. S., Barlat, F., & Lee, S. Y. (2023). Comparison of anisotropic yield functions and calibrations for accurate thickness prediction in hole expansion test. Journal of Materials Processing Technology, 319, 118070. https://doi.org/10.1016/j.jmatprotec.2023.118070

Park, S., Jung, J., Cho, W., Jeong, B. S., Na, H., Kim, S. I., Lee, M. G., & Han, H. N. (2021). Predictive dual-scale finite element simulation for hole expansion failure of ferrite-bainite steel. International Journal of Plasticity, 136, 102900. https://doi.org/10.1016/j.ijplas.2020.102900

Pathak, N., Butcher, C., & Worswick, M. (2016). Assessment of the critical parameters influencing the edge stretchability of advanced high-strength steel sheet. Journal of Materials Engineering and Performance, 25(11), 4919-4932. https://doi.org/10.1007/s11665-016-2316-9

Paul, S. K. (2020a). A critical review on hole expansion ratio. Materialia, 9, 100566. https://doi.org/10.1016/j.mtla.2019.100566

Paul, S. K. (2020b). Effect of punch geometry on hole expansion ratio. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 234(3), 671-676. https://doi.org/10.1177/0954405419863222

Soussi, H., & Krichen, A. (2019). Plastic anisotropy effect on forming kinematics of the hole-flanging process. The International Journal of Advanced Manufacturing Technology, 101, 733-746. https://doi.org/10.1007/s00170-018-2974-x

Yoshida, F., Hamasaki, H., & Uemori, T. (2013). A user-friendly 3D yield function to describe anisotropy of steel sheets. International Journal of Plasticity, 45, 119-139. https://doi.org/10.1016/j.ijplas.2013.01.010

Yu, X., Chen, J., & Chen, J. (2016). Interaction effect of cracks and anisotropic influence on degradation of edge stretchability in hole-expansion of advanced high strength steel. International Journal of Mechanical Sciences, 105, 348-359. https://doi.org/10.1016/j.ijmecsci.2015.11.026