Optimizing the fermentation process of vinegar from fine rice bran

Main Article Content

Abstract

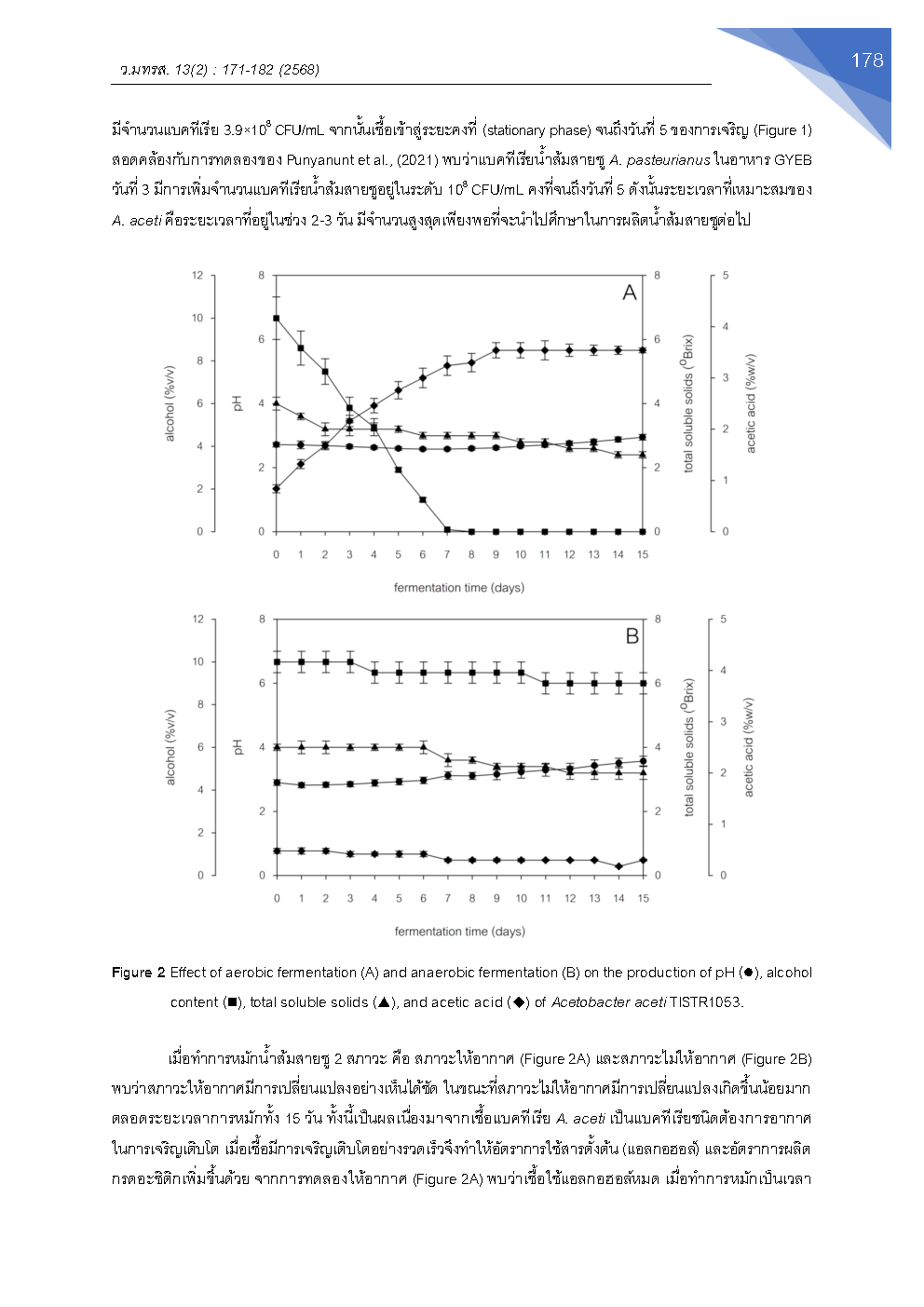

This research aimed to determine the optimal conditions for producing vinegar from fine rice bran through a two-step fermentation process, comprising alcoholic fermentation followed by acetic acid fermentation. Compositional analysis revealed that the fine rice bran contained high levels of protein (17.17g/100g fine rice bran) and carbohydrates (53.01g/100g fine rice bran), making it as an excellent nitrogen and carbon sources for microbial biotransformation. The initial alcoholic fermentation yielded a maximum alcohol concentration of 9.90±0.36% (v/v) by using Look-Pang Sato as an inoculation. Subsequently, this alcohol was used as a substrate for acetic acid fermentation with Acetobacter aceti TISTR1053, which achieved a maximum acetic acid concentration of 3.60±0.06% (w/v) after 9 days under aerated conditions. The findings indicated that fine rice bran is a viable substrate for producing a fermented vinegar with quality comparable to that of commercial rice vinegars. This process effectively adds value to a by-product of the rice milling industry, creating a beneficial and healthful product.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Published manuscript are the rights of their original owners and RMUTSB Academic Journal. The manuscript content belongs to the authors' idea, it is not the opinion of the journal's committee and not the responsibility of Rajamangala University of Technology Suvarnabhumi

References

AOAC. (1993). Official methods of analysis of AOAC international (14th ed.). Association of Official Analytical Chemist, USA. http://lib3.dss.go.th/fulltext/scan_ebook/aoac_1993_v76_n2.pdf

AOAC. (2023). Official methods of analysis of AOAC international (22nd ed.). Association of Official Analytical Chemist, USA. https://www.aoac.org/official-methods-of-analysis

Cheirsilp, B., Satansat, J., Wanthong, K., Chaiyasain, R., Rakmai, J., Suwannarach, N., Kumla, J., Pathom-aree, W., Wang, G., & Srinuanpan, S. (2023). Bioprocess improvement for fermentation of pigmented Thai glutinous rice-based functional beverage (Sato) with superior antioxidant properties. Biocatalysis and Agricultural Biotechnology, 50, 102701. https://doi.org/10.1016/j.bcab.2023.102701

Danwiruthai, P., & Laopaiboon, P. (2006). Fruit wine and sato: How to produce with confidence (2nd ed.). Khlangnanavithaya Publisher. (in Thai)

dela Rosa, J. G. L., & Medina, P. M. B. (2022). Philippine rice wine (Tapuy) made from Ballatinao black rice and traditional starter culture (Bubod) showed high alcohol content, total phenolic content, and antioxidant activity. Food Science and Technology, 42, 45120. https://doi.org/10.1590/fst.45120

Ferronatto, A. N., Rossi, R., Pinto, L. M. N., & Garavaglia, J. (2021). Development of a freeze-dried symbiotic obtained from rice bran. Biotechnology Reports, 30, e00636. https://doi.org/10.1016/j.btre.2021.e00636

Ho, C. W., Lazim, A. M., Fazry, S., Zaki, U. K. H. H., & Lim, S. J. (2017). Varieties, production, composition and health benefits of vinegars: A review. Food Chemistry, 221, 1621-1630. http://dx.doi.org/10.1016/j.foodchem.2016.10.128

Kanauchi, M. (2013). SAKE alcoholic beverage production in Japanese food industry (pp. 39-63). IntechOpen. http://dx.doi.org/10.5772/53153

Kanlyakrit, W., & Booranasawettatham, S. (2005). Identification of yeasts and molds isolated from Thai tradition fermentation starter (Lookpang) for sato industry. Proceedings of 43rd Kasetsart University Annual Conference: Animals, Agro-Industry (pp. 419-426). Bangkok: The Thailand Research Fund. https://kukr.lib.ku.ac.th/kukr_es/index.php?/BKN/search_detail/result/9371 (in Thai)

Krongkeha, W. (2024). Screening and identification of bacteriocin-producing lactic acid bacteria from Thai fermented meat products. RMUTSB Academic Journal, 12(2), 229-242. https://li01.tci-thaijo.org/index.php/rmutsb-sci/article/view/262122 (in Thai)

Kudpeng, C., Soemphol, W., & Tanamool, V. (2016). Study on production of sato from indigenous rice varieties in Nakhon Ratchasima. Proceedings of The National and International Graduate Research Conference 2016 (pp. 371-380). Khon Kaen: Khon Kaen University, Thailand. https://gsbooks.gs.kku.ac.th/59/ingrc2016/pdf/BMP1.pdf (in Thai)

Li, Y., Gao, C., Wang, Y., Fan, M., Wang, L., & Qian, H. (2023). Analysis of the aroma volatile compounds in different stabilized rice bran during storage. Food Chemistry, 405, 134753. https://doi.org/10.1016/j.foodchem.2022.134753

Limtong, S., Sintara, S., Suwanarit, P., & Lotong, N. (2002). Yeast diversity in Thai traditional fermentation starter (Loog-pang). Kasetsart Journal: Natural Science, 36, 149-158. https://www.thaiscience.info/journals/Article/TKJN/10974111.pdf

Limtong, S. (2006). Yeast: Biodiversity and biotechnology. Kasetsart University Publisher. (in Thai)

Massarolo, K. C., de Souza, T. D., Ribeiro, A. C., Furlong, E. B., & de Souza Soares, L. A. (2016). Influence of cultivation Rhizopus oryzae on rice bran on lipid fraction: Fatty acids and phospholipids. Biocatalysis and Agricultural Biotechnology, 8, 204-208. https://doi.org/10.1016/j.bcab.2016.10.002

Moreira, B. P., Draszewski, C. P., Rosa, N. C., Tres, M. V., Zabot, G. L., Pereira, F. C., Abaide, E. R., & Castilhos, F. (2023). Integrated rice bran processing by supercritical CO2 extraction and subcritical water hydrolysis to obtain oil, fermentable sugars, and platform chemicals. The Journal of Supercritical Fluids, 192, 105786. https://doi.org/10.1590/2179-8087.042318

Nazir, N., Fiana, R. M., & Putra, D. P. (2019). Characteristics of black glutinous rice vinegar as traditionally fermented product of yeast Tapai and Acetobacter aceti. Proceedings of IOP Conference Series: Earth and Environmental Science, 347(1), 012049. https://iopscience.iop.org/article/10.1088/1755-1315/347/1/012049/pdf

Pazuch, C. M., Kalschne, D. L., Siepmann, F. B., Marx, I. M. G., Oliveira, T. C. G. D., Spinosa, W. A., Canan, C., & Colla, E. (2020). Optimization and characterization of vinegar produced from rice bran. Food Science and Technology, 40(3), 608-613. https://doi.org/10.1590/fst.13919

Punyanunt, S., Chalermsanyakorn, W., Phadungath, C., & MeunSritharam, L. (2021). Development of instant acetic acid bacteria model for pineapple cider production. King Mongkut’s Agricultural Journal, 39(2), 141-147. https://li01.tci-thaijo.org/index.php/agritechjournal/article/download/204051/171835/884480 (in Thai)

Sangkod, U., Junrod, K., Aiamsaard, K., Thampitak, K., & Hwanhlem, N. (2021). Chemical characteristics of rice bran and its growth enhancement of probiotic Pediococcus acidilactici V202. Naresuan Agricultural Journal, 18(2), e0180203. https://li01.tci-thaijo.org/index.php/aginujournal/article/view/251869/172850 (in Thai)

Sirikhansaeng, P., Koedlap, J., & Nukadram, W. (2020). Glutinous rice fermented vinegar production from Acetobacter pasteurianus TISTR 102. YRU Journal of Science and Technology, 6(1), 1-9. https://li01.tci-thaijo.org/index.php/yru_jst/article/view/242310 (in Thai)

Siripok, S. (2007). Industrail microbiology. Bangkok Software Technology House. (in Thai)

Sornsanit, K., Arlai, A., & Riangmoo, A. (2022, July). Product development of fermented vinegar from Kluai Nam Wa. Proceedings of the 14th NPRU National Academic Conference Nakhon Pathom Rajabhat University (pp. 203-211). Nakhon Pathom: Nakhon Pathom Rajabhat University, Thailand. https://publication.npru.ac.th/jspui/bitstream/123456789/1604/1/npru-24.pdf (in Thai)

Srismatthakarn, P., & Rauhut, D. (2020). Effect of different Saccharomyces cerevisiae strains and nutrients on the formation of SO2-binding and aromatic compounds of Sauvignon blanc wines. RMUTSB Academic Journal, 8(1), 1-14. https://li01.tci-thaijo.org/index.php/rmutsb-sci/article/view/241682 (in Thai)

Taweekasemsombut, S., Tinoi, J., Mungkornasawakul, P., & Chandet, N. (2021). Thai rice vinegars: Production and biological properties. Applied Sciences, 11(13), 5929. https://doi.org/10.3390/app11135929

Wongsa, P., Anantawa, V., Suthiluk, P., Setha, S., Naradisorn, M., Rawdkuen, S., & Shetty, K. (2025). Nutritional quality, volatile organic compounds and element compositions of indigenous upland rice. Journal of Food Composition and Analysis, 142, 107517. https://doi.org/10.1016/j.jfca.2025.107517