Biodiesel Production Process from Crude Palm Oil using Calcium Oxide Derived from Cockle Shells as Economical and Green Catalyst

Main Article Content

Abstract

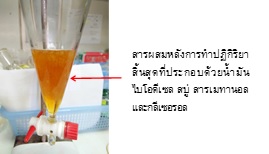

In this study, crude palm oil was used as a starting material for biodiesel production with methanol. Since crude palm oil has a high free fatty acid (FAA) content and gum, consequently, esterification reaction was applied to reduce FAA from 7.25 wt.% to 1.50 wt.% by using H2SO4 as a catalyst. Next step, transesterification reaction was used to transform the crude palm oil which reduced free fatty acid to be biodiesel product catalyzed by cockle shells-derived CaO catalyst. Under the optimal reaction conditions at CaO catalyst loading at 6 wt.%, methanol/oil molar ratio of 12:1 and reaction temperature of 65 °C; %FAME of 98.7% (±1.5) and amount of biodiesel yield as 87% (±2), were achieved within reaction time of 3 h and this catalyst could be reused for at least 4 times. In the last phase of the study, the physicochemical properties of the obtained biodiesel after purification and treatment processes were evaluated and it was found that the biodiesel was of a high quality product according to American Society for Testing and Material (ASTM) methods and European Standard methods (EN14214) for bio-auto fuels.

Article Details

บทความที่ได้รับการตีพิมพ์เป็นลิขสิทธิ์ของ วารสารวิทยาศาสตร์และเทคโนโลยี มหาวิทยาลัยอุบลราชธานี

ข้อความที่ปรากฏในบทความแต่ละเรื่องในวารสารวิชาการเล่มนี้เป็นความคิดเห็นส่วนตัวของผู้เขียนแต่ละท่านไม่เกี่ยวข้องกับมหาวิทยาลัยอุบลราชธานี และคณาจารย์ท่านอื่นๆในมหาวิทยาลัยฯ แต่อย่างใด ความรับผิดชอบองค์ประกอบทั้งหมดของบทความแต่ละเรื่องเป็นของผู้เขียนแต่ละท่าน หากมีความผิดพลาดใดๆ ผู้เขียนแต่ละท่านจะรับผิดชอบบทความของตนเองแต่ผู้เดียว