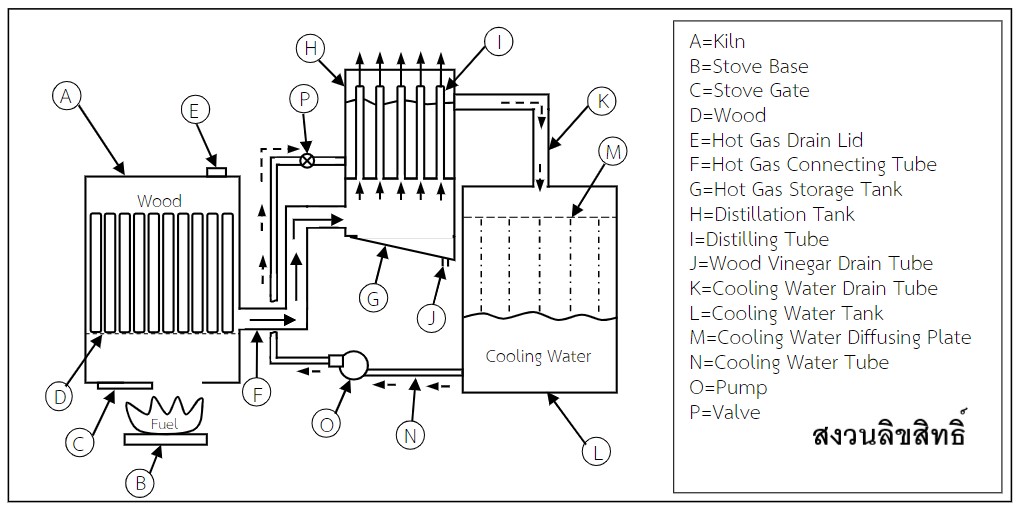

Analysis and Testing of Split Type Wood Vinegar Distilling System

Main Article Content

Abstract

This research design and develop a split type wood vinegar distilling system. The kiln and the distillation part of the system are designed to be separately part. The kiln made from 200 L steel tank connected to distillation tank via hot gas connected tube. The distillation part composed with hot gas storage tank at the bottom of the tank and connected to the distilling tube, which made from copper tubes, to relieve the hot gas. To obtain the wood vinegar, the cooling water is used to flow around the distilling tubes in order to reduce the hot gas temperature inside the tube to below the vapor condensing temperature. The Earleaf acacia wood is used as the raw material in the experiment. The distilled wood vinegar has been collected and reported every hour of 8 hr. The hot gas temperature at inlet and outlet positions of the distilling tubes are also collected. The system behavior has been analyze based on concept of heat transfer. The heat transfer coefficient of two parts, hot gas storage tank and distilling tube, from the analyzing are used to estimate the heat transfer rate. A result from testing found that the developed system can produce the distilled wood vinegar about 5,685 mL within 8 hr. Analysis of hot gas based on inlet temperature of 100-400 ํC gave the heat transfer coefficient between 8-14 W m-2 ํC-1 and the effectiveness of 81-86 % with about 8 % error.

Article Details

use or modification of the articles is prohibited without permission.

statements expressed in the articles are solely the opinions of the authors.

authors are fully responsible for the content and accuracy of their articles.

other reuse or republication requires permission from the journal."