The pickled mango peeling machine using fruit rotating shaft

Main Article Content

Abstract

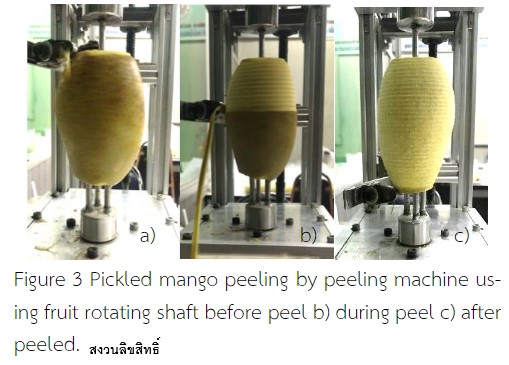

The objective of this research was to design and construct a pickled mango peeling machine using fruit rotating shaft for peeling in the mango process industrial. The peeling machine of pickled mango using fruit rotating shaft consisted of 4 main parts that were a rotating fruit holding shaft set, a screw shaft of sliding knife arm, a blade set and a power transmission set. The testing experiment of the pickled mango peeling machine using rotating shaft, the rotating fruit holding shaft set at the speed of 70, 85, 100 and 115 rpm and the screw shaft of sliding knife arm at the speed of 120, 150, 170 and 190 rpm were tested. It was found that the optimum condition was at the speed of the rotating fruit holding shaft at 100 rpm and the speed of the screw shaft of sliding knife arm at 190 rpm obtained the percentage of pickled mango peeling 97.10%, the capacity rate for peeling the pickled mango was 72.21 kgh-1, the percentage of loss from peeling the pickled mango was 6.23%, the depth and width of peeling the pickled mango were 0.87 mm and 5.40 mm respectively.

Article Details

use or modification of the articles is prohibited without permission.

statements expressed in the articles are solely the opinions of the authors.

authors are fully responsible for the content and accuracy of their articles.

other reuse or republication requires permission from the journal."

References

pdf. Accessed on 16 August 2019.

Jirawan Rojanaphonthip. 2015. Technologychaoban “Woraporn” Delicious processed mango of Padriew city. Available at: https://info.matichon.co.th/techno/ techno.php? srctag=05105150858&srcday=2015-08-15&search=no. Accessed on 1 August 2019.

Noonum., S. 2016. Development of a taro peeler. Master dissertation. Pathum Thani, Thailand: Department of Agricultural Engineering, Rajamangala University of Technology Thanyaburi.

Office of Agricultural Economics, Ministry of Agriculture and Cooperatives. 2016. The value of exports of mangoes in containers. Available at https://www.oae.go.th/oae_report/export_import/export_result.php. Accessed on 20 February 2017.

Olukunle, O.J., Jimoh, M.O. 2012. Comparative analysis and performance evaluation of three cassava peeling machines. International Research Journal of Engineering Science 1 (4), 94-102.

Singh, V., Verma, D. K., V., Singh, G. 2013. Development of Pineapple Peeler-cum-Slicer. Popular Kheti 1 (2), 21-24.

Sirisomboon, P., Pornchaloempong, P. 2011. Instrumental Textural Properties of Mango (cv Nam Doc Mai) at Commercial Harvesting Time. International Journal of Food Properties 14, 441-449.

Thivavarnvongs, T., Nuboon, T. 2006. The development and evaluation of a peeling machine for cassava. Agricultural Science Journal 37 (2 (Suppl.)), 182-185.

Thongsroy, B. 2012. Design and Fabrication of fruit peeling machine using pneumatics system. Master dissertation. Bangkok, Thailand: Department of Agricultural Engineering, King Mongkut's Institute of Technology Ladkrabang.