Design and Fabrication of Biomass and Municipal Solid Waste Carbonizer

Main Article Content

Abstract

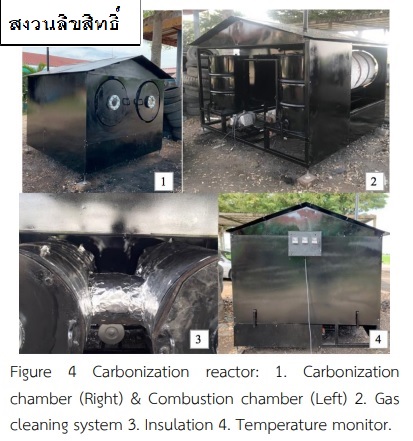

Open burning of municipal solid waste (MSW) and agricultural waste (AW) causes environmental problems. This work designs and fabricates community-scale carbonizer for MSW and AW. It also covers feedstock testing by using MSW and coconut shell waste (CS). Elemental analysis of the products is performed and exhaust gas is analyzed. From the design, the carbonizer consists of a combustion and carbonization chamber. The former generates heat by biomass combustion and delivers to the latter for carbonization process. Flue gas is cleaned by two water scrubbers. The carbonization temperature was about 400 ˚C and the heating rate was about 2.4 ˚C/min. Wet basis yields of char from MSW and CS were 39.2% and 30%, respectively. Carbon contents in the char products of MSW and CS were 83.58% and 37.02%, respectively. Total suspended solid in flue gas was 233 mg/m3 at the oxygen content of 7% condition. This number passes the regulation of flue gas emission. In sum, this research paper provides the idea of open-burning emission reduction by using a community-scale carbonizer.

Article Details

use or modification of the articles is prohibited without permission.

statements expressed in the articles are solely the opinions of the authors.

authors are fully responsible for the content and accuracy of their articles.

other reuse or republication requires permission from the journal."

References

Areeprasert, C., et al. 2018. Biochar Preparation from Simulated Municipal Solid Waste Employing Low Temperature Carbonization Process. IOP Conference Series: Materials Science and Engineering. Vol. 311. No. 1. IOP Publishing.

Williams, Paul T., and Serpil Besler. 1996. The influence of temperature and heating rate on the slow pyrolysis of biomass. Renewable energy 7.3. 233-250.

Park, Sang-Woo, et al. 2012. Torrefaction and low-temperature carbonization of woody biomass: Evaluation of fuel characteristics of the products. Energy 45. 676-685.